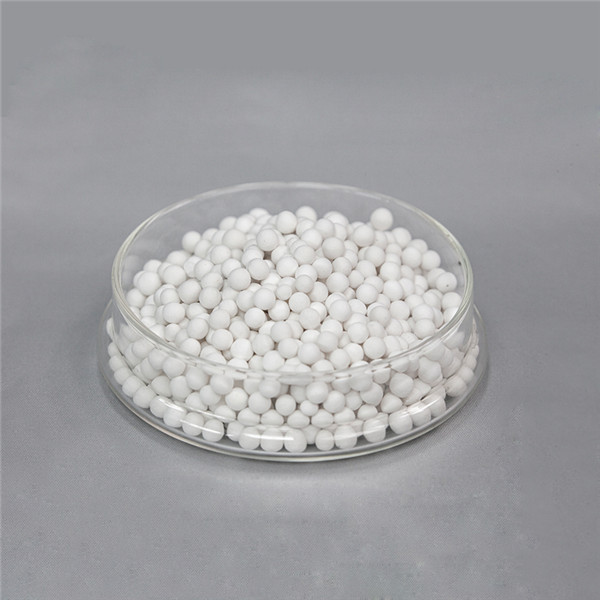

Tus nqi qis rau Txias Ntauwd Media Ceramic Intalox Saddle (1/2 nti)

Peb pheej txhim kho thiab ua kom tiav peb cov khoom thiab kho. Nyob rau tib lub sijhawm, peb tau txais txoj haujlwm ua tiav los ua kev tshawb fawb thiab kev vam meej rau Quoted price for Cooling Tower Media Ceramic Intalox Saddle (1/2 nti), "Ua cov khoom lag luam zoo tshaj plaws" tej zaum yuav yog lub hom phiaj nyob mus ib txhis ntawm peb lub koom haum. Peb ua cov thawj coj uas tsis muaj kev cuam tshuam los nkag siab lub hom phiaj ntawm "Peb Yuav Ua Li Cas Nyob Hauv Pace ua ke nrog Lub Sijhawm".

Peb pheej txhim kho thiab ua kom tiav peb cov khoom thiab kho. Nyob rau tib lub sijhawm, peb tau txais txoj haujlwm ua tiav los ua kev tshawb fawb thiab kev vam meej rauTuam Tshoj Inch Ceramic Intalox Saddles thiab Ceramic Ntauwd Ntim, Tag nrho cov tshuab tuaj txawv teb chaws zoo tswj thiab lav lub machining precision rau cov khoom. Tsis tas li ntawd, peb muaj ib pab pawg neeg tswj hwm cov neeg ua haujlwm zoo thiab cov kws tshaj lij, uas ua rau cov khoom lag luam zoo thiab muaj peev xwm los tsim cov khoom tshiab los nthuav peb cov lag luam hauv tsev thiab txawv teb chaws. Peb ua tsaug cia siab tias cov neeg siv khoom tuaj rau kev lag luam tawg paj rau peb ob leeg.

Daim ntawv thov

Ceramic Intalox Saddle nrog cov kua qaub zoo heev thiab kub ua haujlwm. Lawv tuaj yeem tiv thaiv corrosion ntawm ntau yam inorganic acids, organic acids thiab organic solvents tshwj tsis yog hydrofluoric acid, thiab tuaj yeem siv rau hauv qhov kub thiab txias. Yog li lawv daim ntawv thov ntau yam dav heev.Ceramic Intalox Saddle tuaj yeem siv rau hauv cov kab ziab khaub ncaws, nqus cov kab, txias yees, txhuam cov yees hauv kev lag luam tshuaj, metallurgy kev lag luam, thee gas kev lag luam, kev lag luam oxygen, thiab lwm yam. Ceramic Saddles yog siv nyob rau hauv ob lub ntsiab teb tab sis muaj cov khoom sib txawv nyob ntawm daim ntawv thov. Ib thaj chaw yog cov tshuaj thiab petrochemical kev lag luam thiab lwm qhov yog nyob rau hauv ib puag ncig xws li cov khoom siv RTO.

Technical Data

| SiO2+ Al2O3 | > 92% | CaO | <1.0% |

| SiO2 | > 76% | MgO | <0.5% |

| Al2O3 | > 17% | K2O + Na2O | <3.5% |

| Fe2O3 | <1.0% | Lwm yam | <1% |

Physical & Chemical Properties

| Kev nqus dej | <0.5% | Moh lub hardness | > 6.5 teev |

| Porosity (%) | <1 | Acid kuj | > 99.6% |

| Lub ntiajteb txawj nqus tshwj xeeb | 2.3-2.40 g / cm33 | Alkali tsis kam | > 85% |

| Max ua haujlwm temp | 920 ~ 1100 ℃ |

Cov ntaub ntawv loj thiab kam rau ua

| Loj | Thickness (mm) | Qhov tshwj xeeb (m2/m3) | Tsis muaj Volume (%) | Qhuav Packing (m-1) | Pob Density (kg / m3) |

| 3/4 '' (19mm) | 2-3 | 243 | 70 | 313 | 750 |

| 1 "(25mm) | 3-4 | 250 | 74 | 320 | 700 |

| 3/2 '' (38mm) | 4-5 | 164 | 78 | 170 | 650 |

| 2" (50mm) | 5-6 | 120 | 77 | 130 | 600 |

| 3" (76mm) | 8-10 | 95 | 77 | 127 | 550 |

| Nominal | Alias | Txoj kab uas hla ntawm Deck | Sab nraud txoj kab uas hla | Qhov siab | Phab ntsa Thickness | Dav |

| 1/2 nti | 13 | 13 ± 1.0 | 20 ± 1.4 | 10 ± 1.0 | 2.0 ± 1.0 | 10 ± 2.0 |

| 5/8 nti | 16 | 16 ± 2.0 | 24 ± 1.5 | 12 ± 1.0 | 2.0 ± 1.0 | 12 ± 2.0 |

| 3/4 nti | 19 | 19 ± 5.0 | 28 ± 5.0 | 20 ± 3.0 | 3.0 ± 1.0 | 20 ± 3.0 |

| 1 nti | 25 | 25 ± 4.0 | 38 ± 4.0 | 22 ± 3.0 | 3.5 ± 1.0 | 22 ± 2.0 |

| 1-1/2 nti | 38 | 38 ± 4.0 | 60 ± 4.0 | 35 ± 5.0 | 4.0 ± 1.5 | 35 ± 5.0 |

| 2 nti | 50 | 50 ± 6.0 | 80 ± 6.0 | 48 ± 5.0 | 5.0 ± 1.5 | 40 ± 4.0 |

| 3 nti | 76 | 76 ± 8.0 | 114 ± 8.0 | 60 ± 6.0 | 9.0 ± 1.5 | 60 ± 6.0 |

Lus Cim: 3Inch US loj hom qauv muaj, lwm qhov loj tuaj yeem tsim los ntawm customized.Peb khaws kev txhim kho thiab ua tiav peb cov khoom muag thiab kho. Nyob rau tib lub sijhawm, peb tau txais txoj haujlwm ua tiav los ua kev tshawb fawb thiab kev vam meej rau Quoted price for Cooling Tower Media Ceramic Intalox Saddle (1/2 nti), "Ua cov khoom lag luam zoo tshaj plaws" tej zaum yuav yog lub hom phiaj nyob mus ib txhis ntawm peb lub koom haum. Peb ua cov thawj coj uas tsis muaj kev cuam tshuam los nkag siab lub hom phiaj ntawm "Peb Yuav Ua Li Cas Nyob Hauv Pace ua ke nrog Lub Sijhawm".

Quoted nqe rauTuam Tshoj Inch Ceramic Intalox Saddles thiab Ceramic Ntauwd Ntim, Tag nrho cov tshuab tuaj txawv teb chaws zoo tswj thiab lav lub machining precision rau cov khoom. Tsis tas li ntawd, peb muaj ib pab pawg neeg tswj hwm cov neeg ua haujlwm zoo thiab cov kws tshaj lij, uas ua rau cov khoom lag luam zoo thiab muaj peev xwm los tsim cov khoom tshiab los nthuav peb cov lag luam hauv tsev thiab txawv teb chaws. Peb ua tsaug cia siab tias cov neeg siv khoom tuaj rau kev lag luam tawg paj rau peb ob leeg.