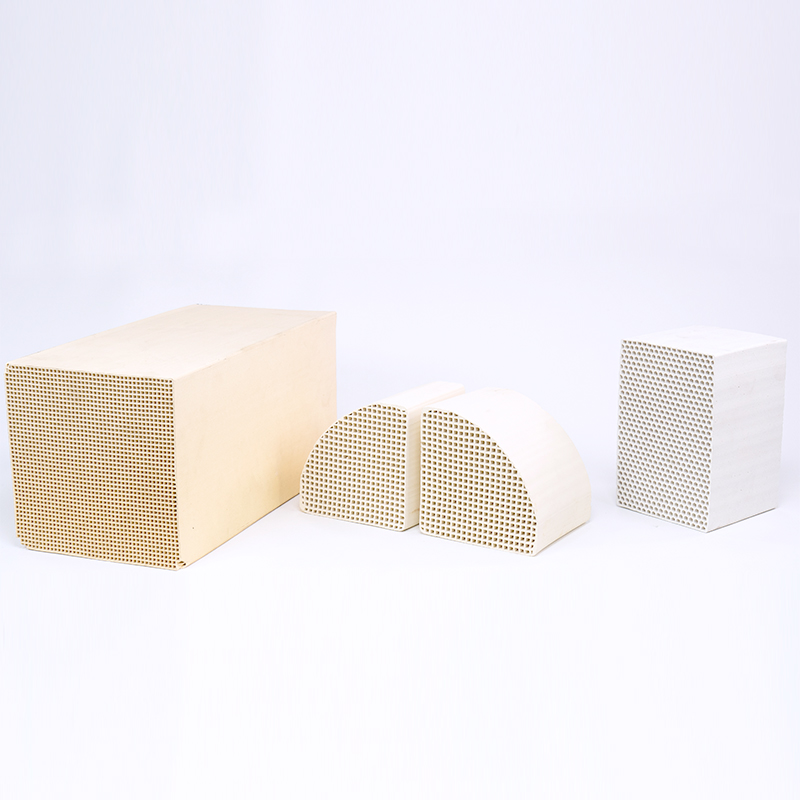

RTO - Kub Hloov Honeycomb Ceramic

Muaj nuj nqi

1.Txo cov thermal poob ntawm cov pa tso pa, thiab txhim kho kev ua haujlwm ntawm cov roj kom txuag tau lub zog raws li.

2.Txhim kho qhov kub thiab txias raws li kev xav, txhim kho cov cua kub kub, ua tau raws li qhov kub thiab txias ntawm cov khoom siv thermal ua kom cov nqi qis calorific roj, tshwj xeeb tshaj yog cov ntawv thov ntau yam ntawm blast furnaces, txhim kho cov txiaj ntsig ntawm calorific nqi roj thiab txo cov emissions los ntawm qis calorific nqi roj.

3.Txhim kho cov ntsiab lus ntawm kev sib pauv cua sov hauv hearths, nce cov khoom tsim tawm, txhim kho cov khoom zoo thiab txo qis rau kev nqis peev hauv cov khoom siv.

4. Txo cov pa tawm ntawm cov khoom siv thermal, txo cov pa phem thiab txhim kho ib puag ncig.

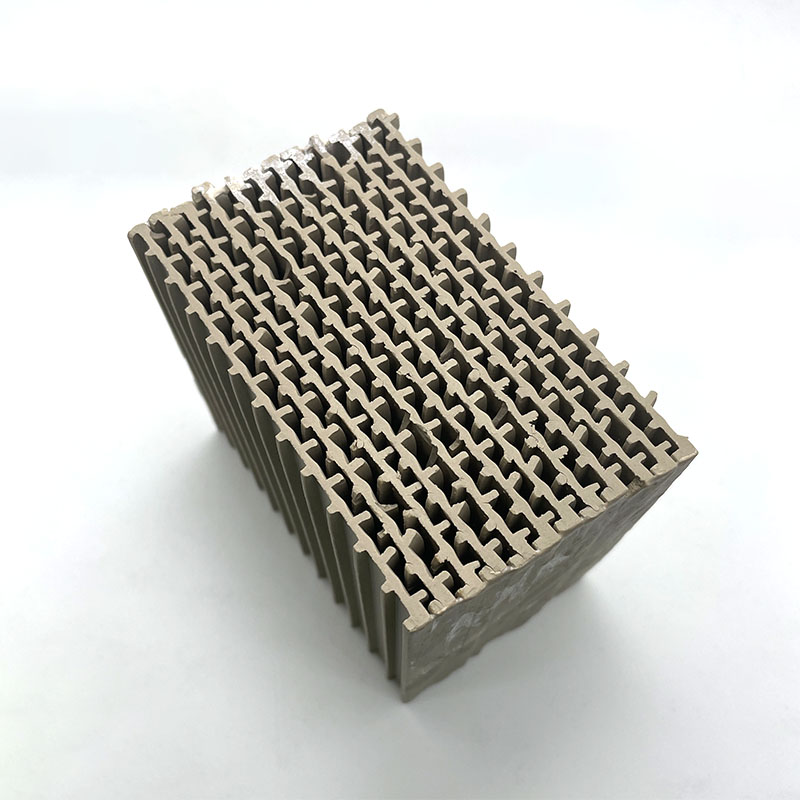

Yam ntxwv

Cov yam ntxwv ntawm honeycomb ceramic regenerator yog raws li nram no: lawv muaj cov cua kub tsis tshua muaj kev nthuav dav, muaj peev xwm ua kom muaj cua sov tshwj xeeb, thaj chaw siab tshwj xeeb, tsis tshua muaj siab poob, tsis muaj thermal tsis kam, zoo thermal conductivity, thermal shock resistant thiab ntau ntxiv. Yog li, nyob rau hauv metallurgy thiab tshuaj industries, nws yog siv raws li HTAC, thaum peb muab recycling lub tshav kub ntawm cov emissions, high efficiency combustion nrog txo NOx. Nws dhau los ua qhov tseeb txuag hluav taws xob thiab txo qis Nox.

Khoom siv: Alumina, Dense Alumina, Cordierite, Dense Cordierite, Mullite, Corundum Mullite thiab lwm yam

Daim ntawv thov

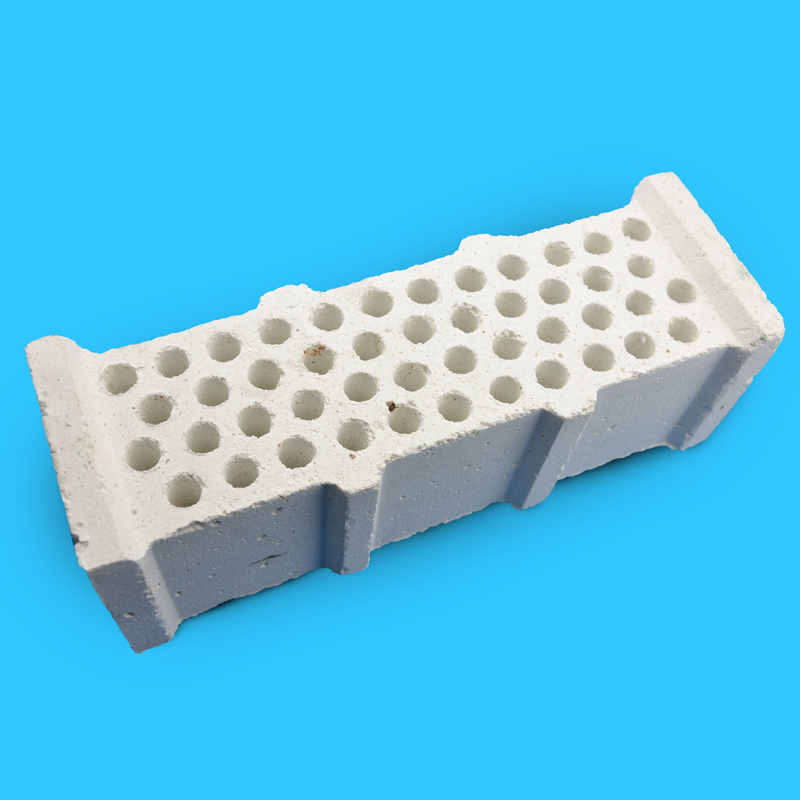

Honeycomb ceramic yog qhov tseem ceeb thiab tseem ceeb ntawm cov khoom siv hluav taws xob kub kub combustion technology (HTAC technology). Nws tau dav siv nyob rau hauv ntau yam laub-steel cua sov rauv, taug kev cua sov rauv, kho cua sov rauv, forging furnaces, melting furnaces, ladle / tundish roasters, soaking furnaces, radiant tube burners, thiab tswb hom furnaces nyob rau hauv lub metallurgical machinery kev lag luam. Rauv, moj tej tawg rauv cua kub cua sov rauv; ntau yam ceramic furnaces thiab ntau yam iav furnaces nyob rau hauv lub tsev cov ntaub ntawv kev lag luam; ntau yam tubular cua sov rauv, tawg furnaces thiab lwm yam kev lag luam furnaces nyob rau hauv petrochemical kev lag luam.

Specifications

100x100x100, 100x150x150, 150x150x150, 150x150x300mm thiab lwm yam

Qhov suav: 25x25, 40x40, 43x43, 50x50, 60x60 thiab lwm yam

Dimension

| Dimension (mm) | Cells (N × N) | Cell ceev (CPSI) | Channel Dav (mm) | Sab hauv phab ntsa Thickness (mm) | Dawb Hla Tshooj (%) |

| 150 × 150 × 300 hli | 20 × 20 | 11 | 6.00 Nws | 1.35 Nws | 64 |

| 150 × 150 × 300 hli | 25 × 25 | 18 | 4.90 ib | 1.00 Nws | 67 |

| 150 × 150 × 300 hli | 32 × 32 | 33 | 3.70 ib | 0.90 ib | 63 |

| 150 × 150 × 300 hli | 40 × 40 | 46 | 3.00 Nws | 0.70 ib | 64 |

| 150 × 150 × 300 hli | 43 × 43 | 50 | 2.80 Nws | 0.65 ib | 64 |

| 150 × 150 × 300 hli | 50 × 50 | 72 | 2.40 Nws | 0.60 ib | 61 |

| 150 × 150 × 300 hli | 59 × 59 | 100 | 2.10 | 0.43 ib | 68 |

Tshuaj muaj pes tsawg leeg

| Yam khoom | Cordierite | Mullite | Alumina Porcelain | High Alumina Porcelain | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Lwm tus | 1.5 | 14 | 3.7 | 8.3 | 5 |

Lub cev muaj zog

| Yam khoom | Cordierite (Porous) | Mullite | Alumina Porcelain | High Alumina Porcelain | Corundum | |

| Qhov ceev (g / cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Kev nqus dej (%) | 23 | 18 | 20 | 13 | 12 | |

| Coefficient ntawm Thermal Expansion (× 10-6K-1) (20 ~ 800 ℃) | ≤3.0 | ≤ 6.0 | ≤6.3 | ≤ 6.0 | ≤8.0 | |

| Thaum tshav kub kub (J / Kg.K) (20 ~ 1000 ℃) | 750-900 Nws | 1100-1300 Nws | 850-1100 Nws | 1000-1300 Nws | 1300-1400 Nws | |

| Thermal conductivity (W / mk) (20 ~ 1000 ℃) | 1.3-1.5 Nws | 1.5-2.3 | 1.0-2.0 Nws | 1.5-2.3 | 5 ~ 10 | |

| Max. Ua haujlwm kub (℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Axial crushing zog (MPa) | Qhuav | ≥11 | ≥ 20 | ≥11 | ≥ 22 | ≥ 25 |

| Immersion | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |